RESEARCH: Arduino Micro-Controller Board

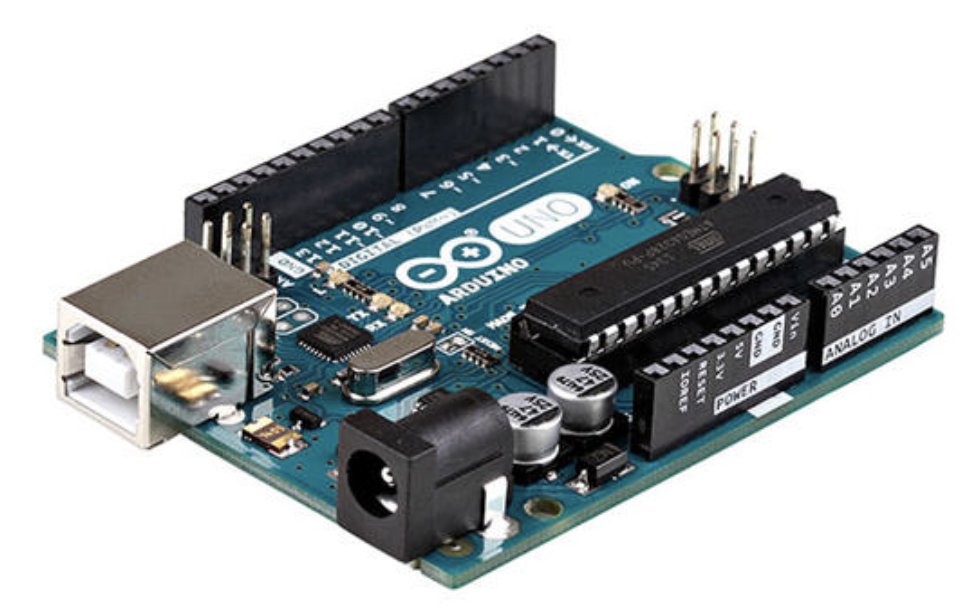

Arduino is a family of open-source microcontroller boards. These boards are equipped with digital and analog General Purpose Input/Output (GPIO) pins that can be interfaces with various electronic circuits. Arduino boards also have various expansion boards (called shields) that adds additional functionality to the Arduino boards (e.g. wifi shield). I started with the Arduino UNO around 2012 for my electronic projects. Over the years various types of Arduino boards were released as well as cheap imitation boards. One of the reasons for the popularity of the Arduino was the simple IDE (using C language) to write the program for controlling the board.

As of 2020, there are several competition that overshadowed the Arduino. Products such as ESP 8266 & 32 provide much more functionality while being much smaller and cheaper. Despite of the competitions, there are still use cases for Arduino in the maker community. Following are some of the Arduino boards that I still utilize in my projects.

Arduino UNO Rev 3 - I still love this original model from the Arduino. - additional details WIP

Arduino Mega 2560 Rev 3 - This was called a BIG brother to the UNO model with its whopping 256K RAM despite of the 8-bit processor limit. I would still argue that the use case for the Arduino supports these smaller capabilities. - additional details WIP

Arduino Nano - This is the smaller brother to the UNO. - additional details WIP

Teensy - This model is a micro USB-based development system with a small (Nano size) footprint. One of its main strong point was the smaller footprint and the larger RAM (64K). I personally never really implemented in my projects as I stayed with the Arduino UNO and Mega and jumped right over to the ESP8266 - additional details WIP

STM32F103C8 - When this model came out, it was referred to as the super-duper Arduino (referring to its 32 bit processor) or a “Small board with a really long name”. This one also, I never got around to using it in my projects, but some day, I would love to implement it in my projects to experience the limitations and advantages. - additional details WIP

Spitfire EV Project - Body work (aka Restoration) phase

Fixing a big dent at the bottom of the trunk

As I start sanding out all the old paint from the car, one of the key task is to hammer out all the dents as best I can. Upcourse, it is much easier said than done in execution.

1/2 inch thick putty from the previous repair - all have to be scraped (aka chiseled) off!!

Lots of rust under the old putty work. Good thing I am scraping it down to the bare metal.

And more chisel work……

Since the trunk lid is doubled layered, and I am not able to get my dolly underneath and hammer it out as usual.

Time to get the stud welder out and “pull” out all the dents.

Just with everything in life, it pays off to spend the time and effort in the beginning to build a solid foundation. Since this phase is identical to the normal “Classic Auto Restoration Project”, I can go slow, learning every inch of of the car and it’s history down to the “bare” metal… and fall in love with it.

Once I get done with the body work (removing all the dents; sanding off the paint down to the bare metal; welding on all the tiny cracks formed in the body/sheet metal over time), I can spray paint the exterior with the gray color Epoxy Sealer and interior frame with the black Epoxy Sealer to protect all the metal. Once that is done (expect 1-2 months from now depending on how much time I can allocate for the project with the other competing projects), I can transition to installing batteries and working on the electronics.

Slow and steady & Keep moving forward!

1979 Triumph Spitfire is here

Spitfire finally came home yesterday. Thanks to Jeff and his friend for going through all the trouble to being the vehicle to me this weekend. I pulled the car out of the garage on Sunday to do some scrubbing and test the batteries. The vehicle was already converted to EV (DC motor, 6x 12v Lead Acid) back in 2010ish so this project will be Conversion Project 2.0

Let the sanding begin!

EV PROJECT PLAN & COST ESTIMATES

WIP - costs are being updated

EV Cost

Spitfire 1500 - $500 (inc tower)

12v Battery - TBD

Seatbelt - TBD

Windshield replace - TBD

Fuse replace - TBD

Paintwork - TBD

AC motor replace - TBD

Dashboard & meters - TBD

Supporting Cost

Garage Expoxy ($150 x3 + accessories $100 = $550)

Car cover

Tire lock x2

Panel Hammer Set ($100 inc jeweler hammer)

Dent repair hammer set

EV PROJECT VISION & GOALS

VISION

With the Tesla and other EV’s commonly seen nowadays on the street, Converted EV’s are still rare. Also, despite of all the technological advances in EV, the problem that is holding us back is still the battery. Battery is too expensive, heavy, slow charging and temperature sensitive. In order to get to know the technical limitations, I needed a platform that I can use to gain a first hand knowledge of the limitations. Also, I needed to test the different approaches in the “Battery Management” techniques and algorithms. Unlike using a modern EV full of sensors and computers that can become and obstacle during the project, a converted “classic car” can will let me focus on the EV components only. Another way to look at it is that I am building a big computerized battery testing platform that has wheels. Eventually, this project will merge with other battery & electric power projects such as battery storage (power wall) project and solar power project.

GOALS - 2018

(X) Join an Electric Vehicle club & research EV conversation process & cost

(C) Decide on a classic car, find a mechanic who can convert, and build a project plan + budget plan

GOALS - 2019 : Approach changed from paying a mechanic to convert the vehicle (faster but more costly) to doing most of the work myself (ideally buying a converted EV or In Prog)

(X) Setup garage as a workstation for EV conversation & charging

(X) Find and buy a converted vehicle & complete body work as needed

Complete necessary electric work & battery installation (Lead acid or Lithium polymer battery)

GOALS - 2020

Complete all required EV conversion work & electric safety controls

Complete car interior and dashboard (including safety belt)

Test run & optimize motor/battery configuration

Complete exterior paint & clear coat